- JayStar Packaging(ShenZhen) LTD.

- jason@jsd-paper.com

Custom Making Packaging Boxes from a Reliable Factory 솔루션

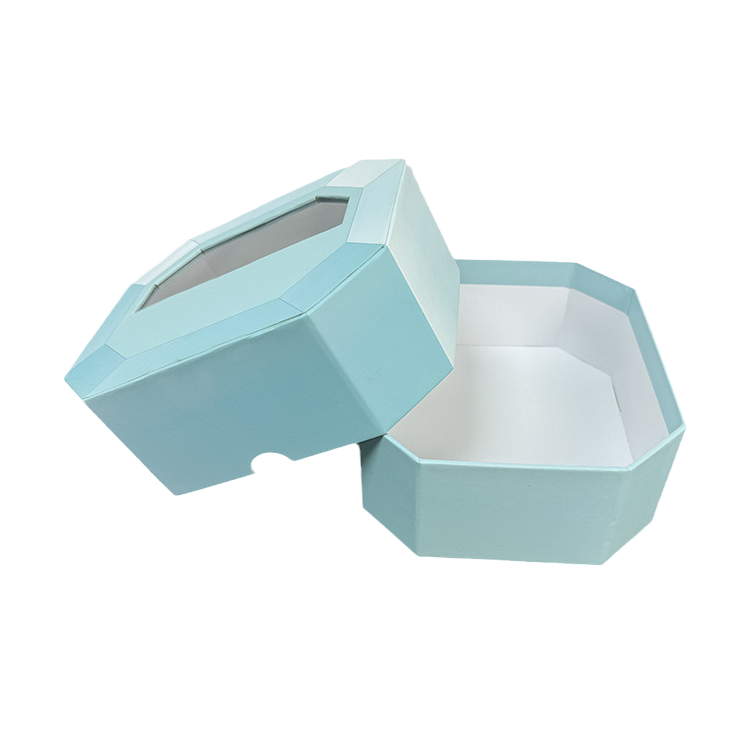

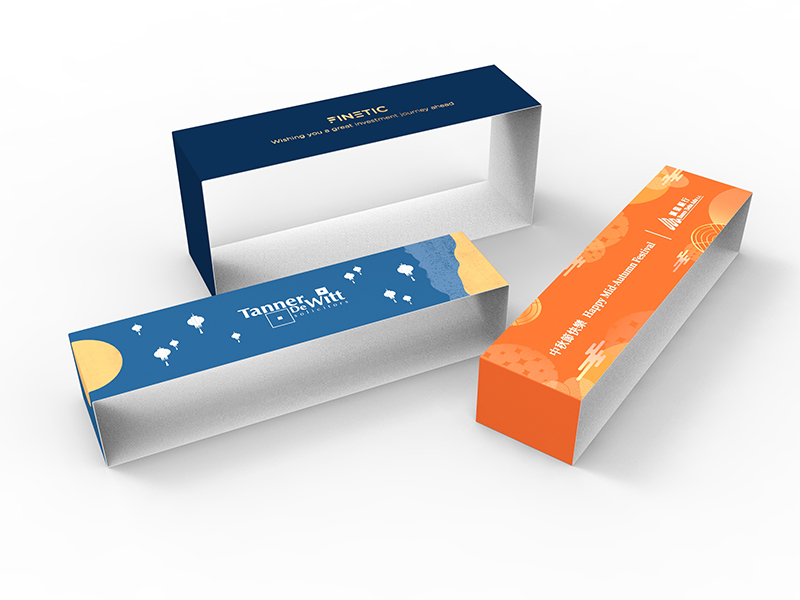

When I think about making packaging boxes, I picture an essential tool for any business. Custom packaging not only showcases your unique brand but also ensures your products are protected during transit. As someone who values quality and creativity, I find that partnering with a dedicated factory makes all the difference. The precision in craftsmanship and attention to detail that a specialized factory offers cannot be overstated. I’ve seen firsthand how custom designs can enhance a product’s appeal on the shelf and improve customer satisfaction. Whether I need sturdy boxes for shipping or elegant designs for retail display, I know I can rely on a factory that understands my vision. Each box is a reflection of my brand’s identity, ready to make an impression. Let's bring your packaging ideas to life and create something remarkable together. Quality and customizability is the key!

Making Packaging Boxes Ahead of the Curve Service Backed by Expertise

In today's fast-paced market, staying ahead of the competition is key to success, particularly in the packaging industry. Effective packaging solutions not only protect products but also enhance brand perception and consumer engagement. With a deep commitment to quality and innovation, many manufacturers are now offering tailored solutions that meet the diverse needs of global buyers. By marrying cutting-edge design with sustainable materials, these companies ensure that their packaging boxes are not just functional, but also capable of making a positive environmental impact. Expertise in the packaging realm is paramount. Successful manufacturers leverage their extensive knowledge to offer insights into trends and best practices, from eco-friendly options to custom designs that cater to specific product requirements. This expertise empowers clients to make informed decisions, fostering collaborations that elevate their brand presence. By focusing on both aesthetics and practicality, businesses can create packaging that resonates with consumers while enhancing supply chain efficiency. As the demand for unique and personalized packaging continues to rise, companies that prioritize innovation and adaptability will lead the pack. Investing in advanced technologies and skilled personnel ensures that manufacturers can meet evolving customer needs and stay relevant. With a strong focus on customer satisfaction and quality assurance, these packaging solutions are designed to keep businesses ahead of the curve, providing a competitive edge in an increasingly crowded marketplace.

Making Packaging Boxes Ahead of the Curve Service Backed by Expertise

| Box Type | Material | Dimensions (inches) | Weight (lbs) | Durability Rating |

|---|---|---|---|---|

| Folding Box | Cardboard | 12 x 8 x 4 | 0.5 | High |

| Rigid Box | Chipboard | 10 x 8 x 2 | 1.2 | Very High |

| Shipping Box | Corrugated Cardboard | 18 x 12 x 6 | 1.5 | Medium |

| Gift Box | Paperboard | 8 x 8 x 4 | 0.3 | High |

| Pizza Box | Flute Board | 14 x 14 x 2 | 0.9 | Medium |

Related Products

Making Packaging Boxes Supplier Products

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat