When it comes to printing, there are two main methods for creating vibrant, high-quality images: spot color printing and CMYK. Both techniques are widely used in the packaging industry to create eye-catching designs on boxes and paper. Understanding the differences between these two printing methods is crucial to achieving the desired effect in your packaging design.

Spot color printing, also known as Pantone Matching System (PMS) printing, is a technique that uses premixed ink colors to create specific hues. This method is particularly suitable for packaging designs that require precise color matching, such as brand logos and corporate identity. Rather than mixing color combinations to achieve a specific hue, spot color printing relies on predefined ink recipes to produce consistent and accurate color from print run to print run.

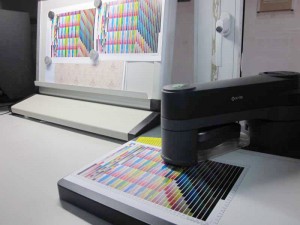

CMYK printing, on the other hand, stands for cyan, magenta, yellow and primary color (black) and is a four-color printing process that uses a combination of these primary colors to create a full spectrum of hues. This method is commonly used for printing color images and graphics because it can produce a variety of colors by layering different percentages of each ink. CMYK printing is often used for packaging designs with complex images and realistic visual effects.

One of the main differences between spot color printing and CMYK is the level of color accuracy. Spot color printing provides precise color matching and is ideal for reproducing brand-specific colors and maintaining consistency across different printed materials. This is especially important in packaging design, as brand recognition relies heavily on the use of consistent colors and logos. In contrast, CMYK printing offers a wider range of colors but can present challenges in accurately replicating specific hues, especially when matching custom brand colors.

Another important factor to consider is cost. Spot color printing can be more expensive than CMYK printing, especially for designs that require multiple spot colors or metallic inks. This is because spot color printing requires mixing and preparing individual ink colors for each print job, which can result in higher production costs. CMYK printing, on the other hand, is more cost-effective for projects involving multiple colors because the four-color process can provide a diverse color palette without the need for custom ink mixing.

In packaging design, the choice between spot color printing or CMYK depends on the specific requirements of the project. For example, brands that rely heavily on consistent color performance may choose spot color printing to ensure that their packaging materials accurately reflect their corporate image. Conversely, packaging designs that focus on vibrant images and dynamic graphics may benefit from the color versatility offered by CMYK printing.

It is worth noting that both spot color printing and CMYK have unique advantages and limitations. While spot color printing excels in color accuracy and brand consistency, CMYK printing offers a wider color spectrum and cost efficiencies for complex designs. Packaging designers and brand owners should carefully evaluate their priorities and budget constraints to determine the printing method that best suits their packaging needs.

Choosing spot color printing or CMYK depends on the specific requirements of your packaging design project. Both methods have their own advantages and considerations in terms of color accuracy, cost, and versatility. By understanding the differences between spot color printing and CMYK, packaging professionals can make informed decisions to achieve the desired visual impact and brand image in packaging materials.

Post time: Jan-11-2024