UV inks for screen printing have become increasingly popular in recent years due to their many advantages over traditional inks. This special ink is designed for screen printing and cures, or hardens, when exposed to ultraviolet (UV) light. There are two main types of UV inks used in screen printing: black ink and white ink.

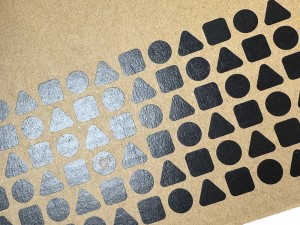

Screen UV black ink is a popular choice for many screen printing applications. This type of UV ink is known for its deep, rich colors and ability to produce sharp, crisp detail on a variety of materials. It is commonly used for printing on products such as promotional items, apparel and packaging. The UV curing process allows the ink to dry quickly, significantly reducing production time and increasing overall efficiency.

One of the main advantages of using screen printing UV black ink is its versatility. This ink can be used on a variety of substrates, including paper, cardboard, plastic, metal, glass and fabric. This makes it ideal for businesses and printers working with a variety of materials and products.

Screen printing UV white ink, on the other hand, is typically used for printing on dark or colored substrates. Traditional white inks often struggle to provide the necessary coverage on these materials, resulting in dull or faded prints. However, UV white ink is highly opaque and provides excellent coverage on a variety of surfaces, even on black or colored backgrounds.

UV white ink is also known for its durability. When cured, it forms a strong, long-lasting bond with the substrate, making it resistant to scratches, abrasion and fading. This makes it ideal for products that require frequent handling or harsh conditions, such as outdoor signage, industrial labels and sporting goods.

In addition to durability, screen printing UV white ink offers excellent brightness and vibrancy. This ink is formulated to provide high levels of opacity and brightness, even on dark substrates. Therefore, it is a popular choice for companies and designers looking to create eye-catching, high-impact visuals on their products.

When considering using UV inks for screen printing, it is important to choose a reputable ink supplier to ensure the best results. Companies should look for ink manufacturers with a proven track record of producing high-quality UV inks and providing excellent customer support. They should also consider factors such as ink compatibility with existing equipment and the availability of technical assistance.

UV inks for screen printing are a versatile and effective option for businesses and printers looking to produce high-quality, durable prints on a variety of substrates. Whether using black ink for its rich color and versatility, or white ink for its opacity and vibrancy, UV ink offers a range of benefits that can help businesses stand out in a competitive market. With the right suppliers and equipment, companies can harness the power of UV inks to enhance their printing capabilities and create stunning, impactful visuals.

Post time: Dec-08-2023