Pallets are a medium that transforms static goods into dynamic ones. They are cargo platforms and mobile platforms, or in other words, movable surfaces. Even goods that lose their flexibility when placed on the ground immediately gain mobility when placed on a pallet. This is because goods placed on a pallet are always in a ready state to enter into motion.

Transportation packaging is an essential part of the packaging industry, as it ensures that products are securely and safely transported from one location to another. One of the primary components of transportation packaging is pallets. Pallets are available in various types and designs, and each type of pallet has its own unique features and benefits.

Types of pallets:

1.Wooden pallet

Wooden pallets are the most traditional and widely used type of pallet. There are mainly two types of wooden pallets: stringer pallets (American pallets) and block pallets (European pallets). Stringer pallets are the standard type of pallet used in North America and are commonly referred to as "American pallets."

Stringer pallets are characterized by their simple structure, easy production, and overall durability. Their basic design allows for efficient use of space and better load stability. However, the main disadvantage of this type of pallet is that they are typically only designed for two-way entry, and if they are designed with a "V" shaped notch on the stringers, they can be used for four-way entry. This limitation makes them less suitable for manual handling and more suitable for automated handling systems.

▲American pallet

Block pallets, on the other hand, are the standard type of pallet used in Europe and are commonly referred to as "European pallets." They have a more complex structure than stringer pallets, and their overall durability is slightly lower. However, they are designed for four-way entry, making them more convenient to use than stringer pallets.

▲European pallets

Wooden pallets are widely used in the packaging industry due to their low cost, easy availability, and durability. However, they are also associated with some drawbacks, such as the risk of contamination and the need for regular maintenance.

In conclusion, understanding the different types of pallets available is essential for selecting the best pallet for product requirements. While wooden pallets are the most traditional and widely used type of pallet, they are not always the best choice for every application. Companies should carefully consider their product and handling requirements to select the most suitable pallet for their needs.

2.Plastic Pallets

According to the production process, plastic pallets can be classified into two categories: injection molded and blow molded.

Domestic injection-molded pallets: because of their slightly lower load-bearing capacity, pallet structures are generally designed for single-sided use. Double-sided use requires the welding or bolting of two single-sided pallets, so they are less commonly produced.

▲Injection-molded pallet

Domestic blow-molded pallets: compared to injection-molded pallets, they have greater load-bearing capacity, stronger impact resistance, and a longer lifespan. However, all of the products are double-sided, which makes them unsuitable for use with manual pallet jacks and pallet lift trucks.

▲Four-way entry blow molded pallet

Imported plastic pallets: currently, imported plastic pallets are generally divided into two categories.

Traditional plastic pallets: the raw materials are more stable, but the price is higher.

New-type plastic pallets, also known as compression-molded pallets, have lower production costs and higher load-bearing capacity, and are the new trend in pallet development.

3.Wood-plastic composite pallet

The wood-plastic composite pallet is a new type of composite material pallet. It combines the advantages of wooden pallets, plastic pallets, and metal pallets. Its disadvantage is that it has a relatively high self-weight, which is about twice that of wooden and plastic pallets, and it is slightly inconvenient for manual handling, resulting in higher production costs. It has been widely used in developed countries in the West.

▲Wood-plastic composite pallet

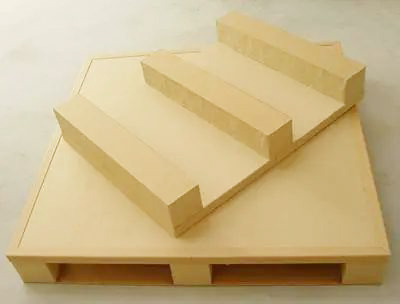

4.Paper pallet

Paper pallets, also known as honeycomb pallets, use scientific principles of mechanics (honeycomb structure) to achieve good physical properties. They have the advantages of being lightweight, low cost, exempt from export inspection, and environmentally friendly and recyclable, and are mostly used as disposable pallets. However, their load-bearing capacity is relatively small compared to other pallets, and their waterproof and moisture-proof properties are poor.

▲Paper pallet

5.Metal pallets

Metal pallets are mainly made by molding and welding steel or aluminum alloys, and they are the strongest and most corrosion-resistant pallets with the best load-bearing capacity. However, their own weight is relatively heavy (for steel pallets), and the price is high. They are mainly used in special fields such as petroleum and chemical industry with special requirements for pallets.

▲Metal pallets

6.Plywood pallet

The plywood pallet is a new type of pallet that has emerged in the development of modern logistics. It mainly uses multi-layer composite plywood or parallel laminated veneer lumber (LVL), also called three-ply board. After bonding, it is processed through high-temperature and high-pressure treatment. The plywood pallet can replace pure wooden pallets, with a clean appearance and free from fumigation, meeting environmental requirements and suitable for one-time export use. It is currently a popular substitute for wooden pallets in foreign countries.

▲Plywood pallet

7.Box pallet

A box pallet is a type of pallet with four sides of sideboards, some of which have a top board and some do not. The box panels come in three types: fixed, folding, and detachable. The four sides have board, grid, and mesh styles, so a box pallet with a mesh fence is also called a cage pallet or warehouse cage. Box pallets have strong protection capabilities and can prevent collapse and cargo damage. They can load goods that cannot be stably stacked and have a wide range of applications.

▲Box pallet

8.Molded Pallet

Molded pallets are made by molding wood fiber and resin glue, and some are mixed with plastic pellets and supplemented with paraffin or additives. They are mostly used as disposable pallets. Its load-bearing performance, firmness, and cleanliness are better than disposable wooden or paper pallets, but the price is slightly higher.

▲Molded Pallet

9.Slip sheet

A slip sheet is a flat board with winged edges extending from one or more sides. It is a loading auxiliary tool that does not require moving a pallet during goods placement and handling. With a special push/pull device installed on a forklift, a slip sheet can be used instead of a pallet for transportation and storage.

▲Slip sheet

10.Column pallets

Column pallets are developed based on flat pallets, and they are characterized by the ability to stack cargo (usually up to four layers) without compressing the goods. They are mostly used for packing materials, rods, pipes, and other cargo.

▲Column pallets

Post time: Feb-24-2023