- JayStar Packaging(ShenZhen) LTD.

- jason@jsd-paper.com

Top China Manufacturer of Foil Stamping and Embossing Techniques

When it comes to enhancing the visual appeal of your products, I know that foil stamping and embossing techniques can make a real difference. These methods don’t just add a touch of elegance; they also elevate your brand’s image in the eyes of potential customers. As a manufacturer based in China, I take pride in offering these premium services, ensuring that every detail is meticulously crafted to meet your standards. Whether you need striking foil accents or deep embossing for a textured finish, my team and I are dedicated to bringing your vision to life. I understand that in the B2B market, first impressions are crucial, and the right techniques can help your products stand out. Let's work together to create stunning designs that capture attention and drive sales. Your satisfaction is my priority, and I'm here to help you achieve the unique look your brand deserves.

Foil stamping and embossing techniques For the Current Year Your Trusted OEM Partner

In today’s competitive packaging landscape, the art of foil stamping and embossing has become increasingly vital for brands aiming to elevate their products' aesthetic appeal. These techniques not only enhance visual and tactile experiences but also convey a sense of quality and sophistication that attracts discerning consumers. As a trusted OEM partner, we prioritize innovation and precision in our foil stamping and embossing processes, ensuring that our clients stand out in the global marketplace. Foil stamping involves applying a metallic or pigmented foil onto a substrate using heat and pressure, creating vibrant visuals with compelling depth. This technique can dramatically transform packaging designs, making logos pop and captivating shelf presence. On the other hand, embossing creates a raised design that adds texture to packaging elements, enhancing the tactile experience. Together, these methods serve as powerful tools for establishing brand identity and distinguishing products in crowded retail environments. As we move through the current year, it’s crucial for businesses to embrace these advanced techniques to remain relevant and appealing. By collaborating with a reliable OEM partner, companies can leverage cutting-edge technology, sustainable materials, and expert craftsmanship to create packaging solutions that resonate with global consumers. Elevating your product presentation through foil stamping and embossing not only helps you stand out but also fosters a lasting connection with your audience.

Foil Stamping and Embossing Techniques for the Current Year

| Technique | Description | Applications | Year Introduced | Popular Materials |

|---|---|---|---|---|

| Hot Foil Stamping | A technique where metallic or pigment foil is applied to a surface using heat and pressure. | Business cards, invitations, packaging | 1980s | Paper, cardboard, synthetic materials |

| Cold Foil Printing | A method where foil is applied without heat, using an adhesive to attach the foil to the substrate. | Labels, packaging, graphics | 2000s | Paper, plastic films |

| Embossing | A process that creates a raised design on a surface by pressing it through a die. | Book covers, greeting cards, luxury packaging | 19th Century | Paper, leather, plastic |

| Debossing | Similar to embossing, but creates an indented design on the substrate. | Stationery, wallets, packaging | 19th Century | Paper, leather, textiles |

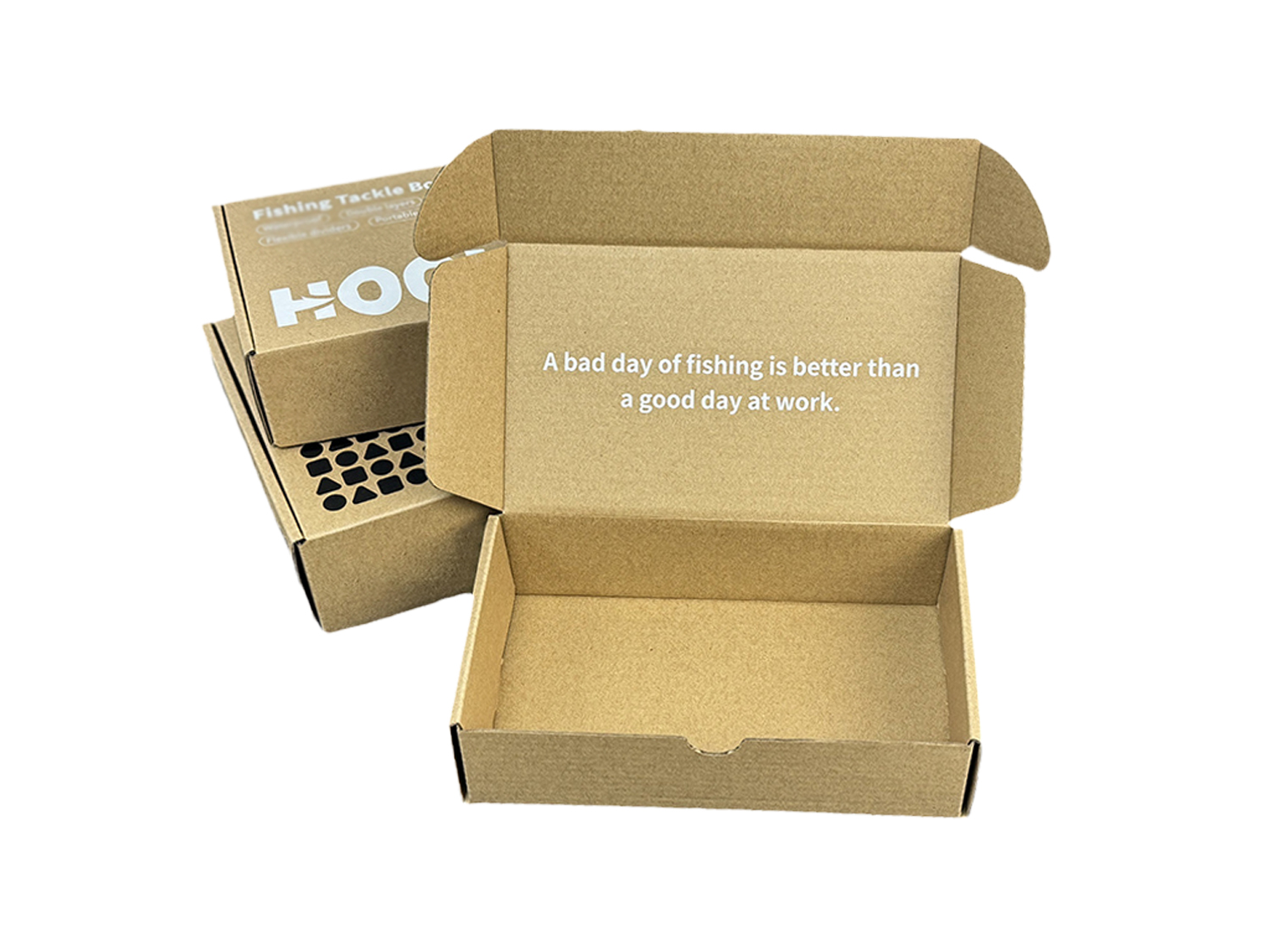

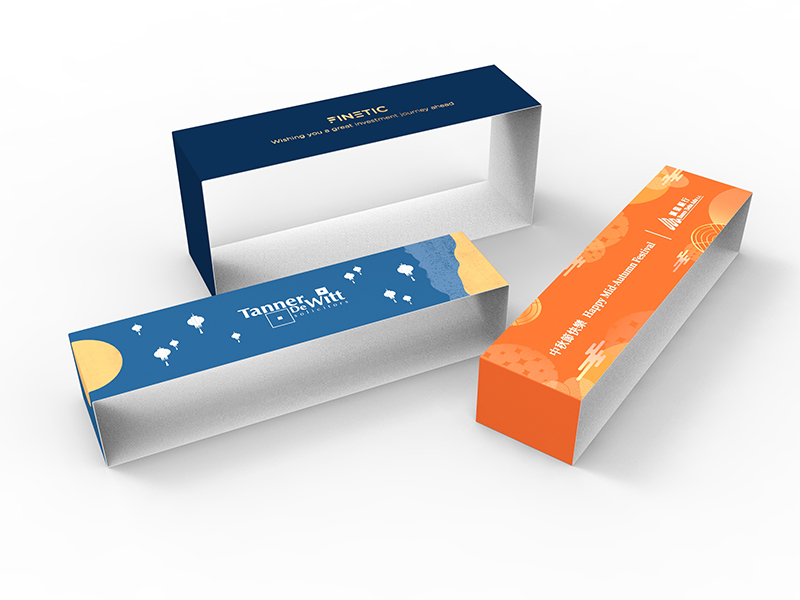

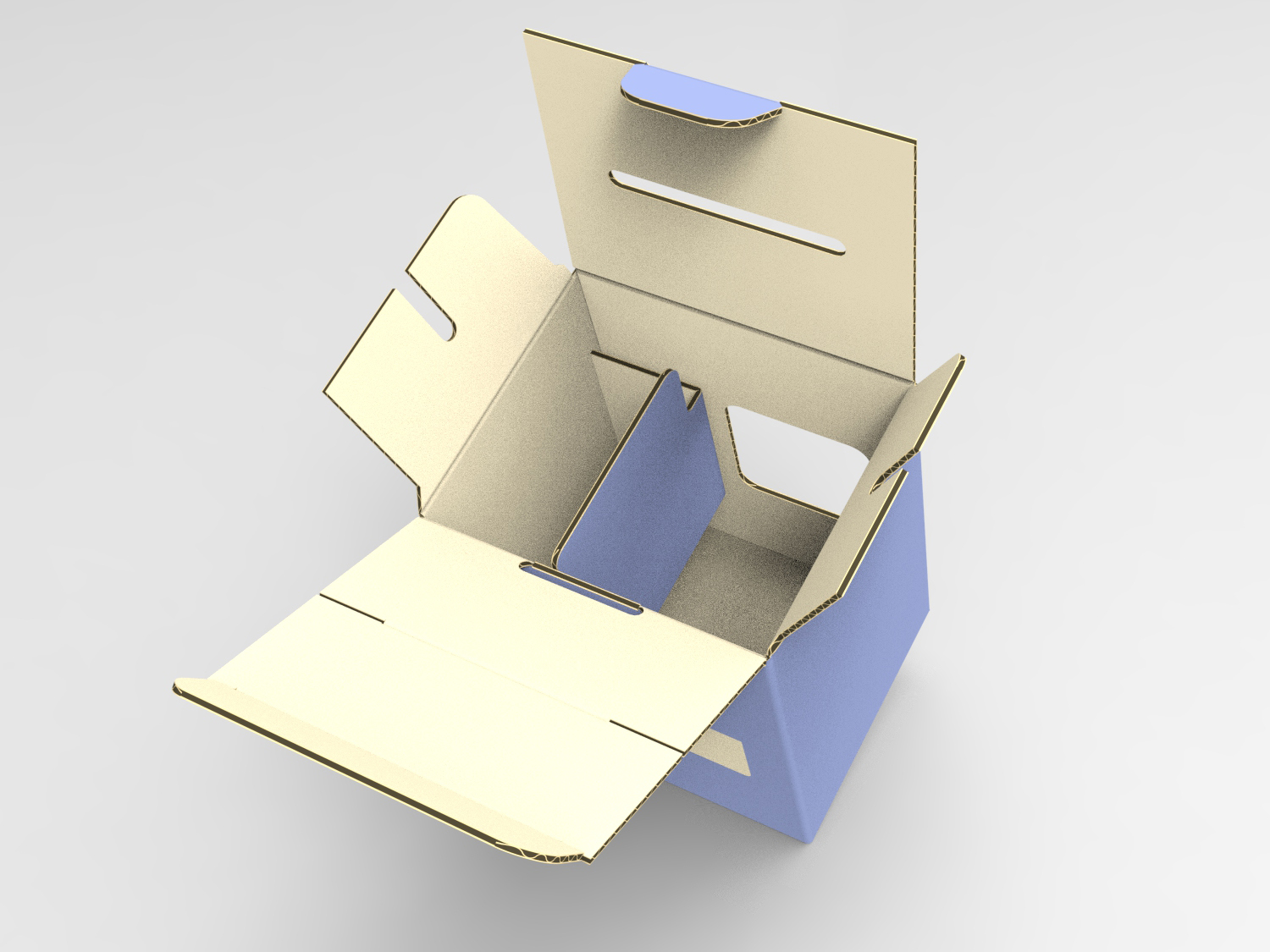

Related Products

Foil stamping and embossing techniques Products Exceeds Industry Benchmarks

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

WeChat