One: Types of paper corner protectors: L-type/U-type/wrap-around/C-type/other special shapes

01

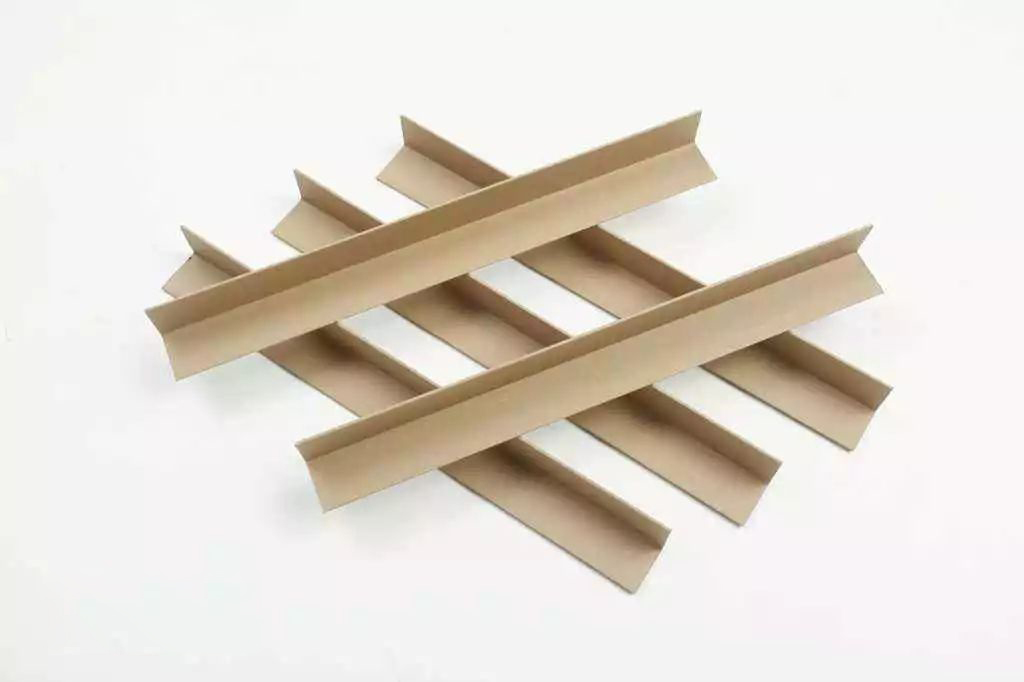

L-Type

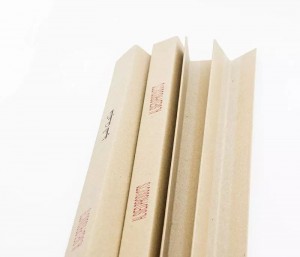

The L-shaped paper corner protector is made of two layers of kraft cardboard paper and the middle multi-layer sand tube paper after bonding, edge wrapping, extrusion shaping, and cutting.

As shown in the picture, it is our most commonly used and common paper corner protector.

Due to the continuous improvement of demand, we have designed and developed a new L-type corner protector style.

02

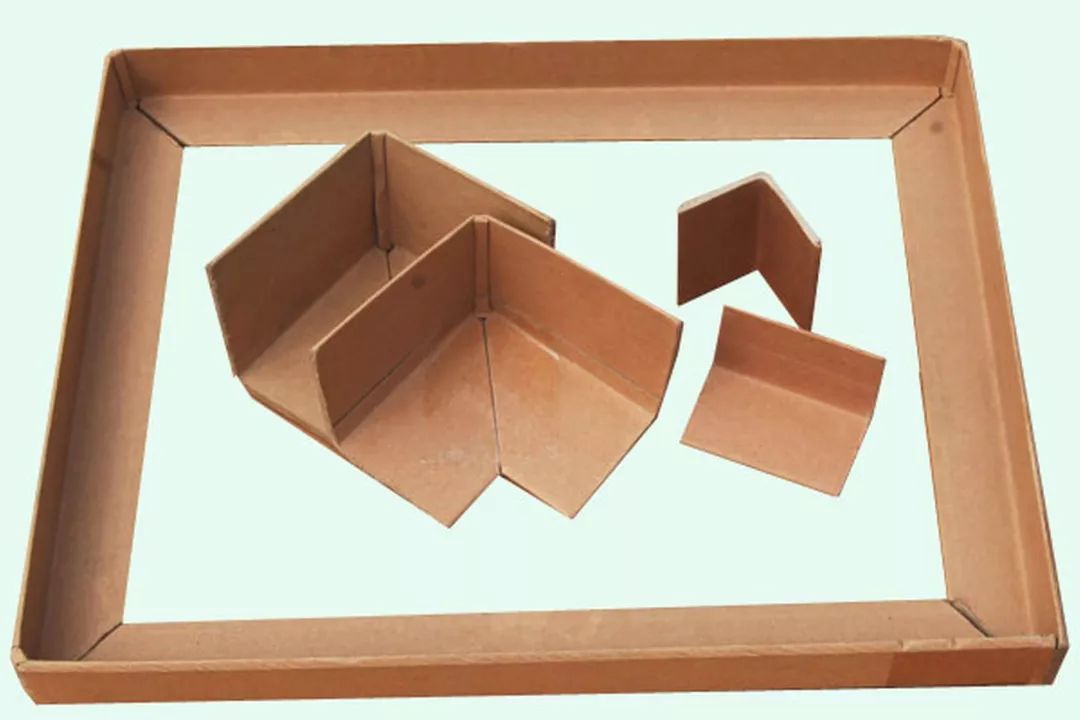

U-Type

The material and process of U-type corner protectors are basically the same as those of L-type corner protectors.

U-type corner protectors can also be processed like this:

U-type paper corner protectors are mainly used for honeycomb panels, and are mainly used in the home appliance industry. In addition, U-shaped paper corner protectors can also be used for carton packaging, door and window cartons, glass packaging, etc.

03

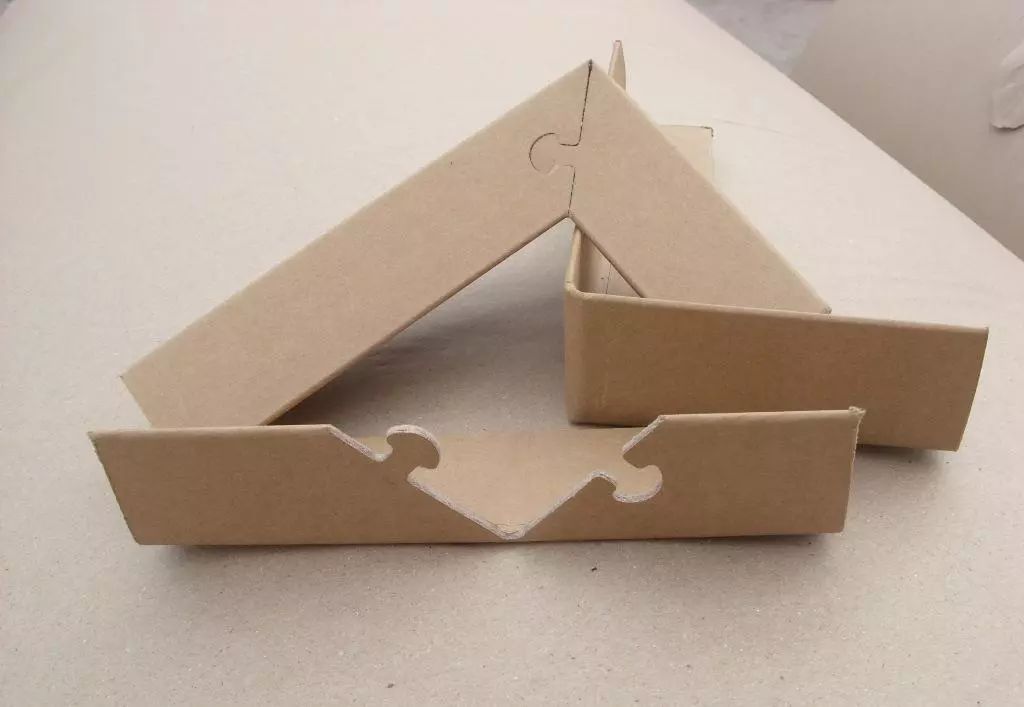

Wrap-around

It is obtained after a period of improvement, and is often used to replace the original angle iron used in heavy-duty packaging, effectively reducing costs.

04

C-Type

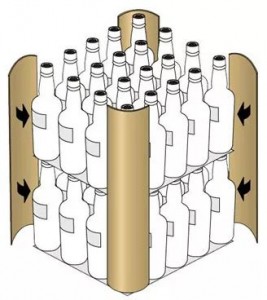

In some special cases and special structural designs, some packaging engineers also use directional paper tubes and round paper tubes as corner protectors. Of course, at this time, its function is not only the role of "corner protection". As shown in the picture: the combination of square paper tube, U-type corner protector and honeycomb cardboard.

Two: The production process of paper corner protector

Paper corner protectors are made of two layers of kraft cardboard paper and multiple layers of sand tube paper in the middle through bonding, edge wrapping, extrusion and shaping, and cutting. The two ends are smooth and flat, without obvious burrs, and perpendicular to each other. Instead of wood, 100% recycled and reused, with high strength rigid package edge protectors.

Three: Application case sharing of paper corner protector

01

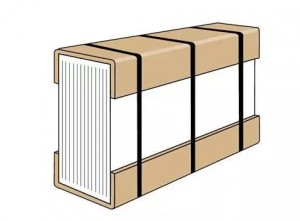

(1): Protect the edges and corners during transportation, mainly to prevent the packing belt from damaging the corners of the carton. In this case, the requirements for corner protectors are not high, and there is basically no requirement for the compressive performance of corner protectors. Customers pay more attention to cost factors.

In order to save costs, some customers only use a small piece of paper corner protector on the packing belt.

(2) Fix the product during transportation to prevent it from being scattered.

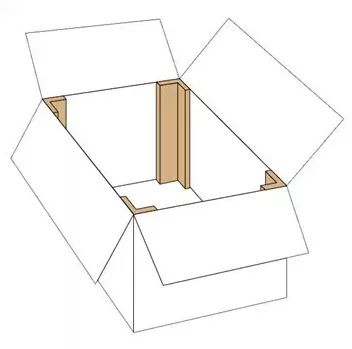

(3) Put it in the carton to increase the compression resistance of the carton. In this way, the use of high-strength cardboard can be avoided as much as possible, and the cost can be reduced. This is a very good solution, especially when the amount of cartons used is small.

(4) Heavy carton + paper corner:

(5) Heavy-duty honeycomb carton + paper corner: often used to replace wooden boxes.

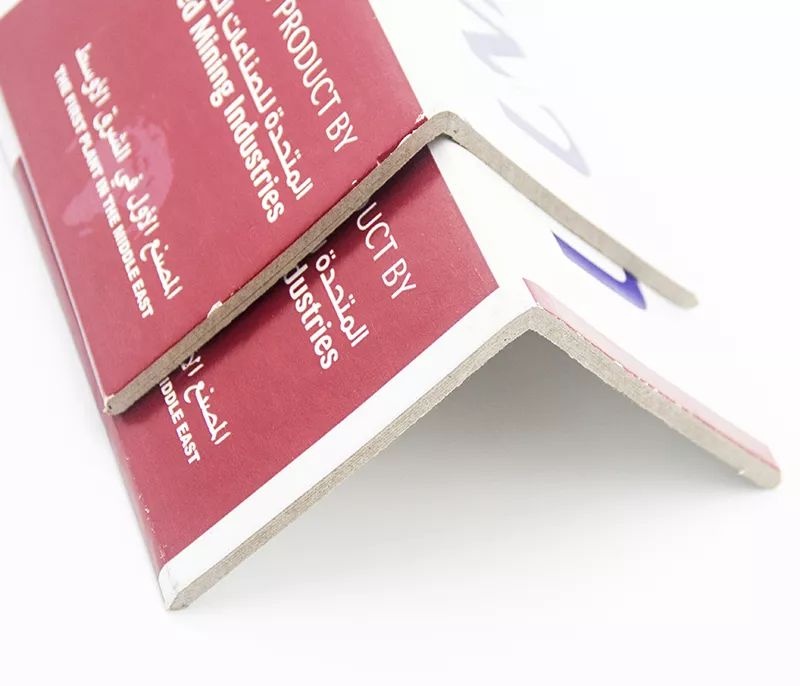

(6) Paper corner protection + printing: First, it can increase the aesthetics of paper corner protection, second, it can achieve visual management, and third, it can enhance recognition and highlight brand effect.

01

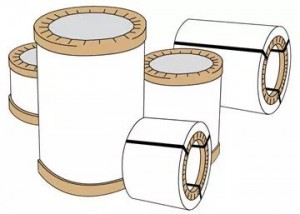

Application cases of U-type corner protectors:

(1) Application on honeycomb cardboard boxes:

(2) Direct packaging products (commonly used in door panels, glass, tiles, etc.).

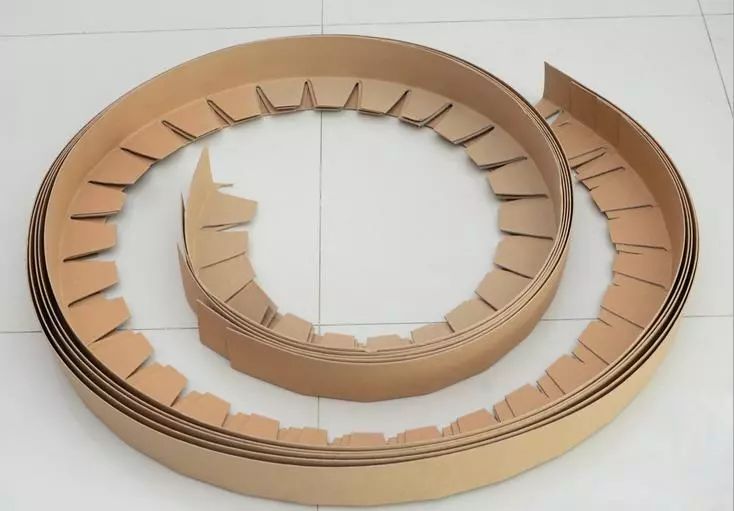

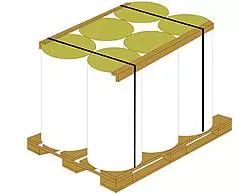

(3) Applied to pallet edging:

(4) Applied to the edge of carton or honeycomb carton:

03

Other application cases of corner protection:

Four: Precautions for selection, design and use of L-type paper corner protectors

01

Since the L-type corner protector is the most widely used, we mainly discuss with the L-type corner protector today:

First of all, clarify the main function of the paper corner protector, and then choose the appropriate corner protector.

---The paper corner protector only protects the edges and corners of the carton from being damaged by the packing tape?

In this case, the principle of price priority is generally followed. Try to choose cheap corner protectors, and the design can only be used for partial protection to minimize the use of corner protector materials.

---Does the paper corner protector need to play the role of fixing the packing box?

In this case, it is necessary to pay attention to the performance of the corner protector, mainly including thickness, flat compressive strength, bending strength, etc. In short, whether it is hard enough and not easy to be broken.

At this time, the combined use of packing tape and stretch film is also more important. Their reasonable use can significantly enhance the performance of paper corner protectors. Especially for this kind of barrel-shaped product, the position of the packing belt must be the main one, and it is best to fix the waist of the barrel with the packing belt.

---The paper corner needs to increase the carton's compression resistance?

In this case, people often use it wrong, or they do not fully utilize the effect of increasing the pressure resistance of the paper corner protector.

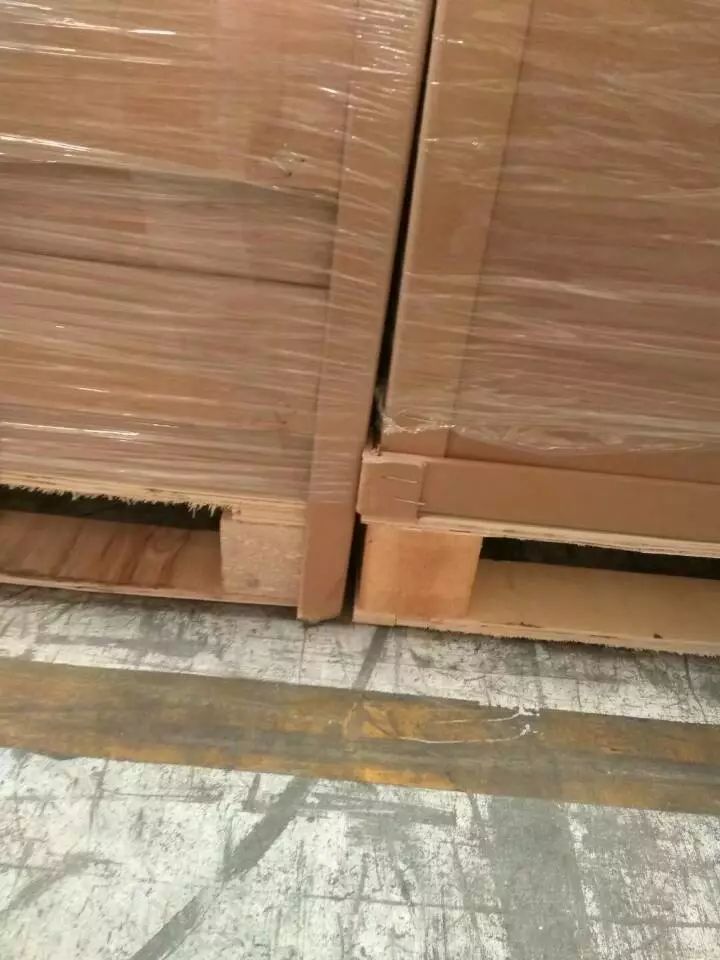

Mistake 1: The corner of the paper is suspended and unable to bear the force. As shown below:

In order to maximize the loading rate of the pallet, the packaging engineer designed the carton size to almost completely cover the surface of the pallet.

In the figure, the height of the paper corner guard is the same as the total height of the stacked cartons, and the lower part is flush with the height of the cartons and the upper surface of the pallet. In this case, the paper corner protector can hardly support the surface of the pallet. Even if it is on the top of the pallet, it is easy to separate from the pallet surface during transportation. At this time, the paper corner protector is suspended and loses its supporting function.

Designing paper corners like this can only play a prescribed role, and has no effect on increasing the compressive strength:

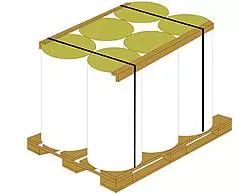

How to design and use corner protectors reasonably and correctly?

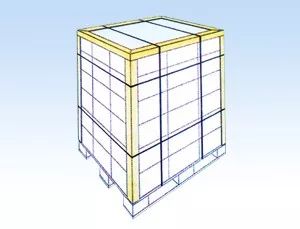

As shown below:

1. There must be corner guards around the top.

2. The 4 vertical corner protectors should be inserted into the top corner protectors.

3. The bottom should be fixed to the bottom, or be effectively fixed on the tray surface to ensure that the corner of the paper can bear the force.

4. Use stretch film.

5. Drive 2 nails horizontally.

Five:Conventional technical standards for paper corner protectors

01

Appearance standard of paper corner protector:

1. Color: The general requirement is the original color of the paper. If there are special requirements, it shall be judged according to the customer's standard.

2. The surface is clean, and there must be no obvious dirt (oil stains, water stains, markings, sticky marks, etc.) and other defects.

3. The cut edge of the paper corner should be neat, without burrs, and the width of the crack on the cut surface should not exceed 2MM.

4. The surface of the paper corner protector should be flat, the angle per meter length should not be greater than 90 degrees at right angles, and the longitudinal bending should not be greater than 3MM.

5. No cracks, soft corners and cracks are allowed on the surface of the paper corner protector. The size error on both sides of the corner should not be greater than 2MM, and the thickness error should not be greater than 1MM.

6. The gluing on the contact surfaces of the paper corner paper and core paper should be uniform and sufficient, and the bonding should be firm. No layer degumming is allowed.

02

Strength standard:

Different strength standards are formulated according to different requirements of the company. Generally, it includes flat compressive strength, static bending strength, adhesive strength and so on.

For detailed requirements and other requirements, you can send an email or leave a message

Today I will share it with you here, and welcome everyone to discuss and correct.

Post time: Jan-10-2023