In the whole printing and packaging industry, color box packaging is a relatively complex category. Because of the different design, structure, shape and technology, there is often no standardized process for many things.

Common color box packaging single paper box structure design, mainly divided into two parts: tubular packaging box and disc packaging box.

1.Tube type packing box

Tubular packaging structure design

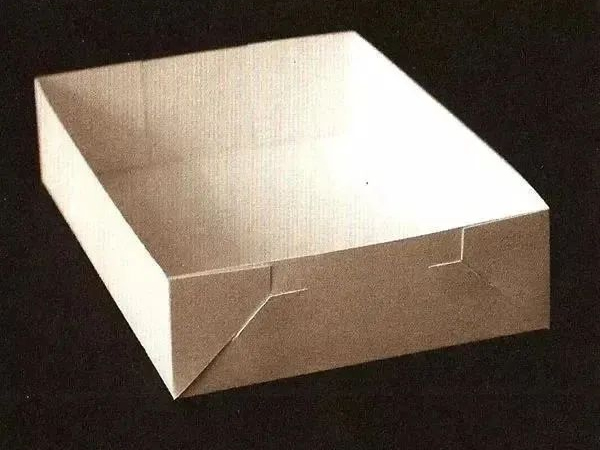

Tubular packaging box is the most common form of daily packaging, most color box packaging such as: food, medicine, daily supplies, etc., all use this packaging structure. Its characteristics are in the molding process, the cover and the bottom of the box need to flap folding assembly (or adhesive) fixed or sealed, and most of the monomer structure (expansion structure for a whole), there is a sticky mouth on the side of the box body, the basic form of the box is quadrilateral, can also be extended to polygon on the basis of this. The structural characteristics of tubular packaging boxes are mainly reflected in the assembly of the cover and the bottom. Here is a look at the different cover and bottom structures of tubular packaging boxes.

(1) The box cover structure of the tubular packing box

The box cover is loaded into the entrance of goods, but also the export of consumers to take goods, so in the structural design requirements of simple assembly and open convenient, both to protect the goods and to meet the requirements of specific packaging, such as multiple opening or one-time anti-counterfeiting open way. The structure of the tube box cover mainly has the following ways.

01

Insert shake cap type

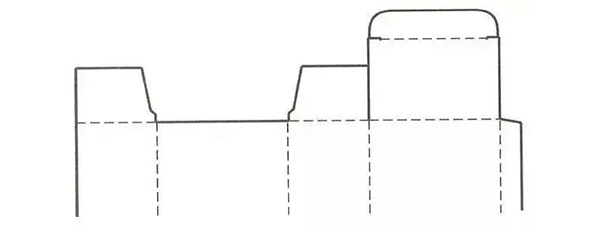

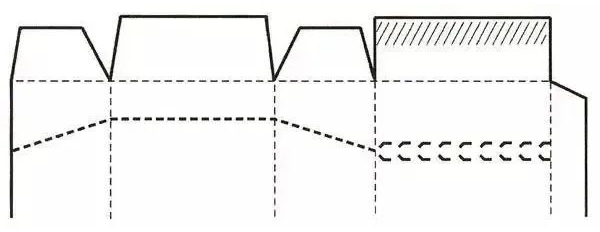

The case cover has three parts of the shaking cover, the main cover has an extended tongue, in order to insert the case body to play a closed role. Attention should be paid to the occlusal relation of the rocking cover in the design. This cover is most widely used in tubular boxes.

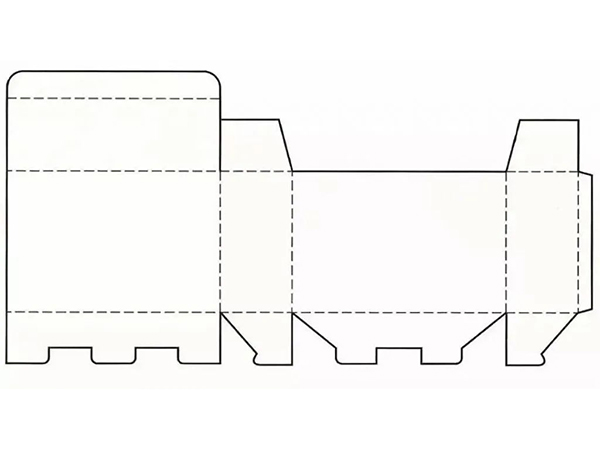

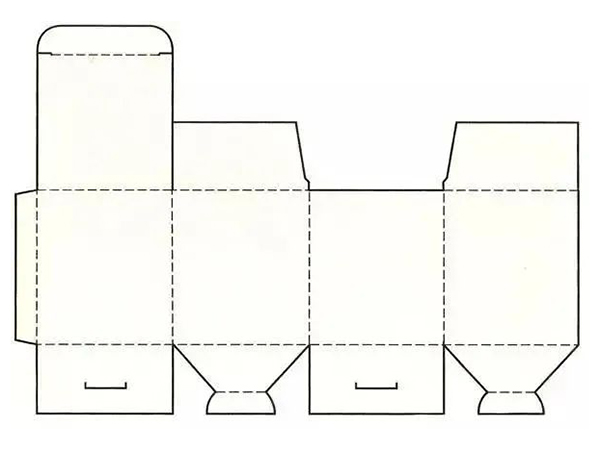

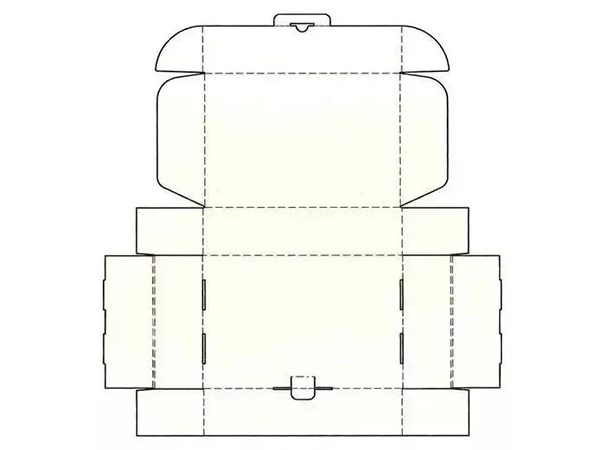

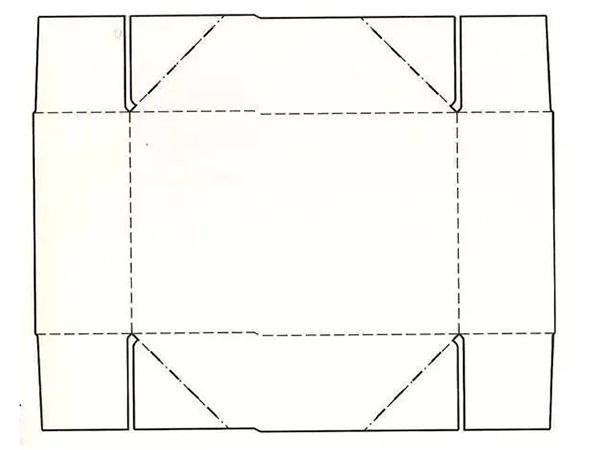

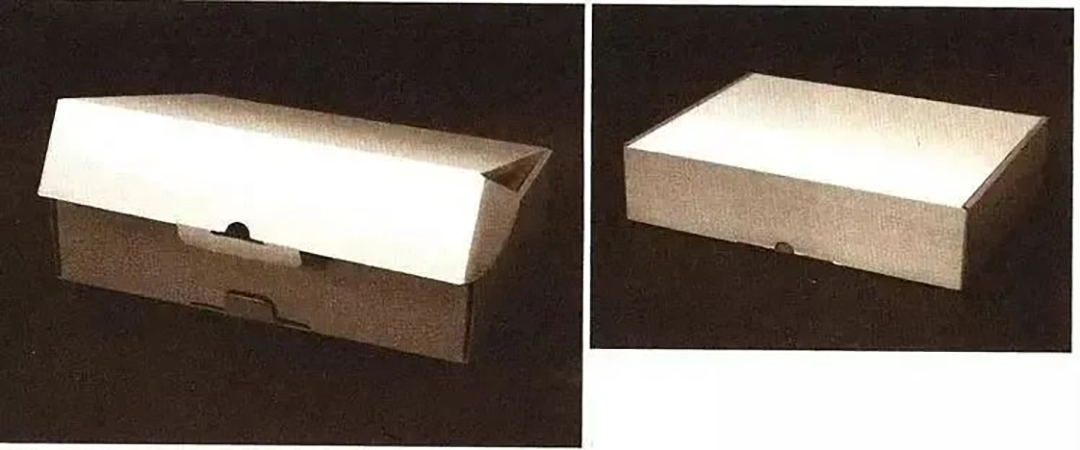

(Insert swinging cover structure expansion diagram)

02

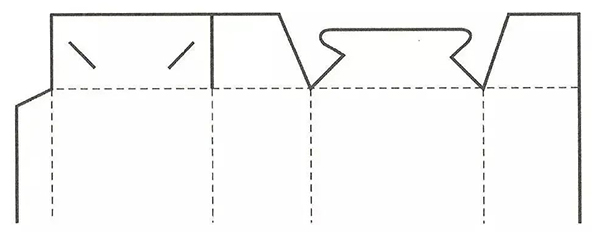

Mortise lock type

A combination of plug and lock, the structure is stronger than the insert shake cap type.

(Structure expansion diagram of latch type box cover)

03

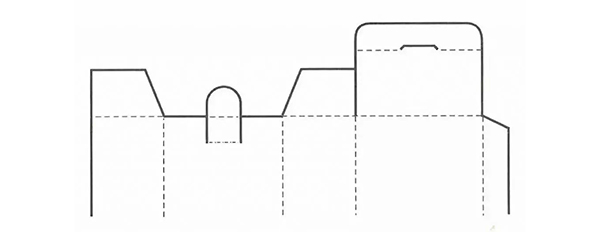

Swing cover double safety insert

This structure makes the shaking cap subject to double bite, very firm, and the shaking cap and tongue bite can be omitted, more convenient to repeat the use of opening.

(Structure expansion diagram of double safety insert box cover with shaking cover)

04

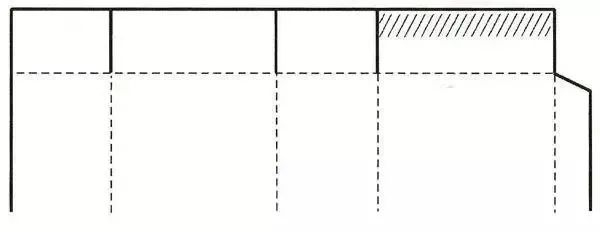

Adhesive sealing type

This bonding method has good sealing and is suitable for automatic machine production, but it cannot be opened repeatedly. Mainly suitable for packaging powder, granular goods, such as washing powder, cereal, once opened, can not be reused.

(Structure expansion diagram of Fusible sealing box cover)

05

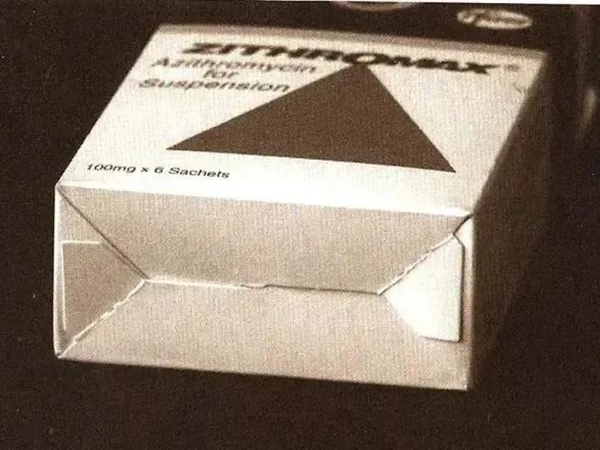

Disposable anti-counterfeiting

The characteristic of this type of packaging structure is the use of tooth-shaped cutting lines, which destroys the packaging structure when the consumer opens the packaging, preventing people from reusing the packaging for counterfeiting activities. This kind of packaging box is mainly used in pharmaceutical packaging and some small food packaging, such as film packaging / tissue paper packaging boxes are currently also using this opening method.

(Structure expansion diagram of disposable security box cover)

(2)The bottom structure of the tubular packing box

The bottom of the box bears the weight of the product, so it emphasizes firmness. In addition, when loading goods, whether it is machine filling or manual filling, simple structure and convenient assembly are the basic requirements. The bottom of the tube packing box mainly has the following ways.

01

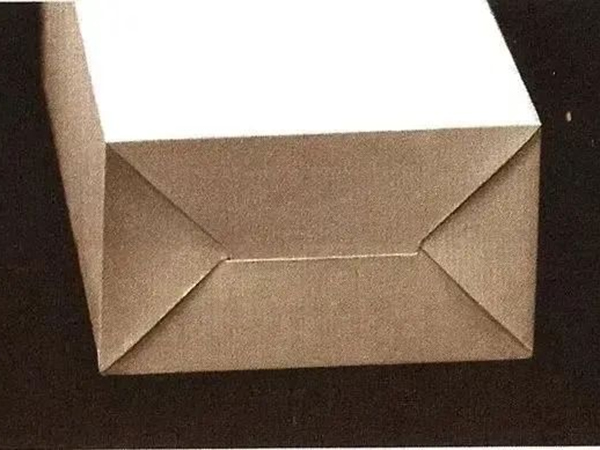

self-locking bottom

The four wing parts at the bottom of the tubular packing box are designed to produce an occlusal relationship with each other. This kind of bite is completed by two steps: "buckle" and "insert". It is easy to assemble and has a certain load-bearing capacity. It is widely used in tubular packaging boxes.

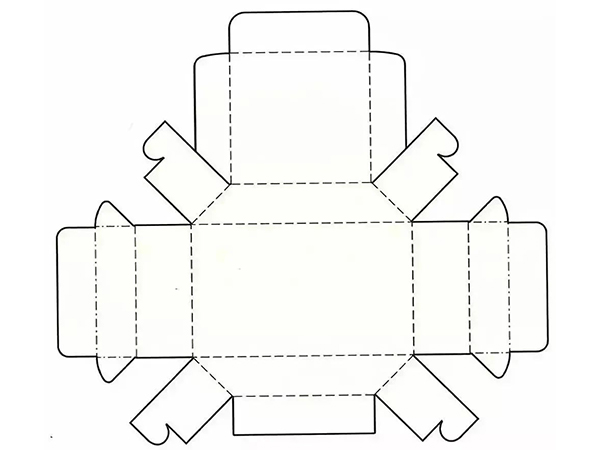

(Expansion diagram of pin type self-locking bottom structure)

02

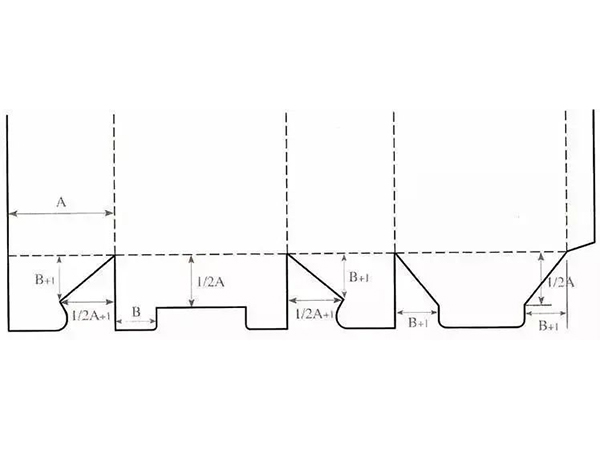

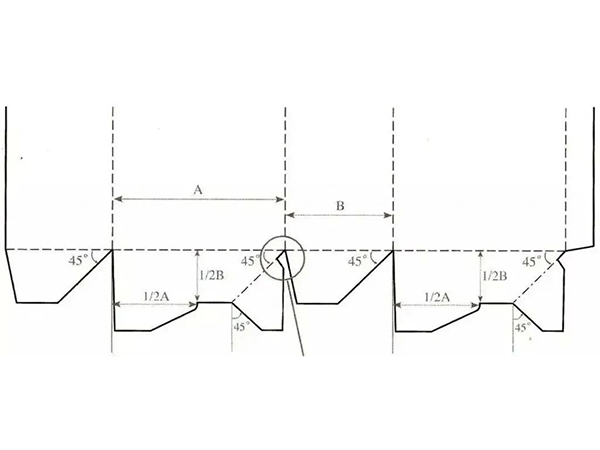

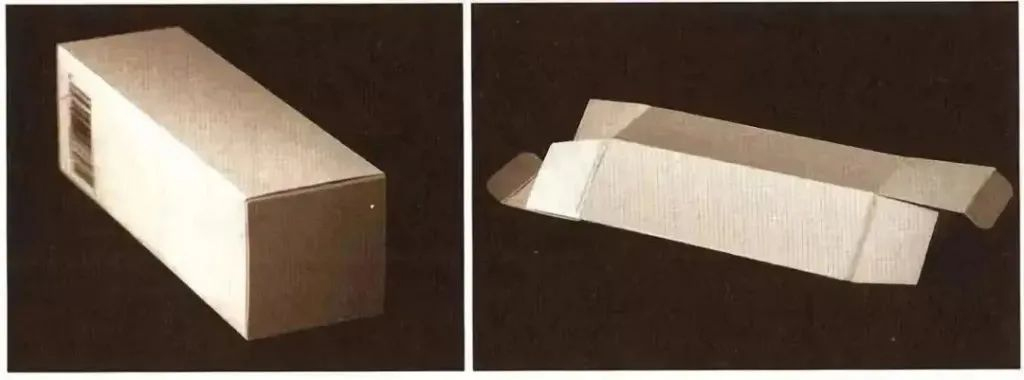

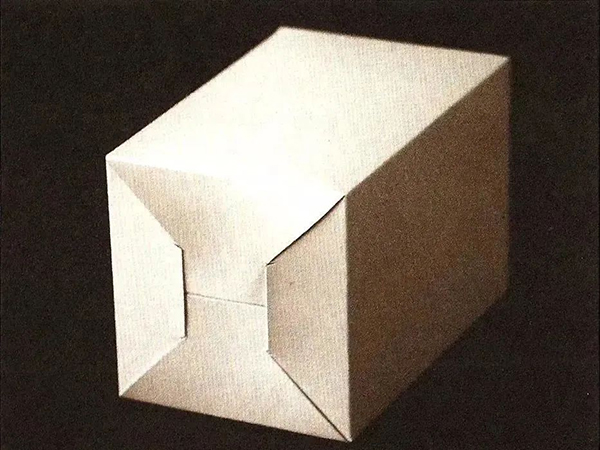

Automatic lock bottom

Automatic lock bottom box used processing method in the process of the adhesive, but still be able to flatten after bonding, when used as long as the open box, with will automatically restore lock close state, use very convenient, save work time saving, and good bearing capacity, suitable for automatic production, general high bearing weight goods packaging design choose structure of this kind of design.

(Automatic bottom locking structure expansion diagram)

03

Shake cover double socket type back cover

The structure is exactly the same as that of the plug-in lid. This design structure is easy to use, but the bearing capacity is weak. It is usually suitable for packaging small or light-weight commodities such as food, stationery, and toothpaste. It is the most common packaging box design structure.

(Expanded view of the double-socket back cover structure of the rocker cover)

04

Other evolutionary structures

According to the above common basic box structure model, other structural forms can also be evolved through design.

(Expanded view of plug-in structure)

(Expanded view of plug-in structure)

(Expansion diagram of latch type structure)

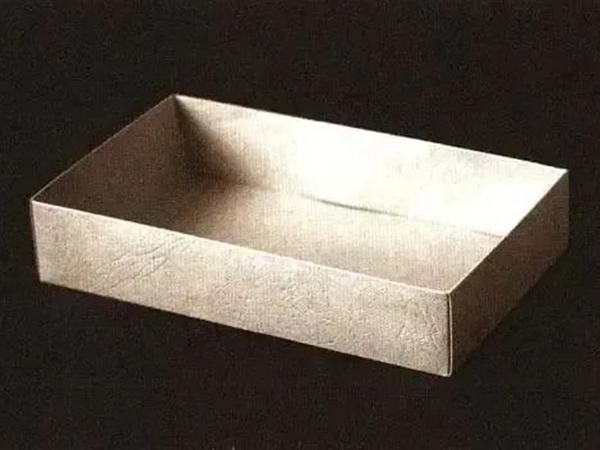

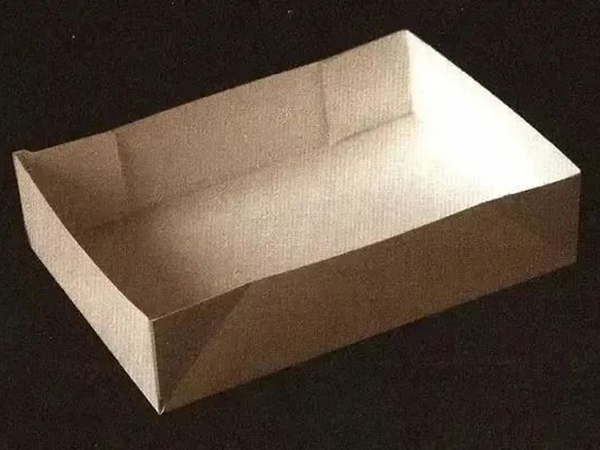

2.Tray type packing box

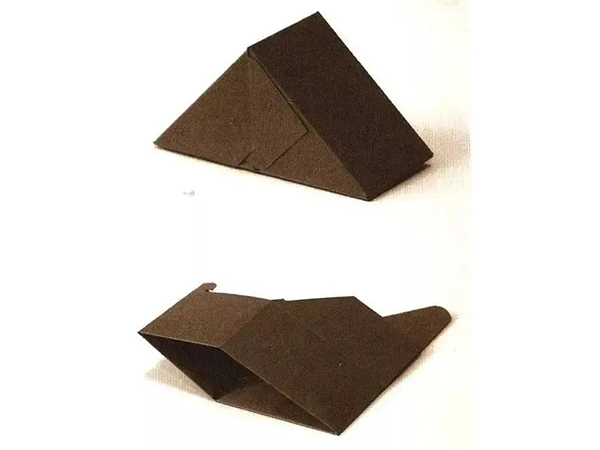

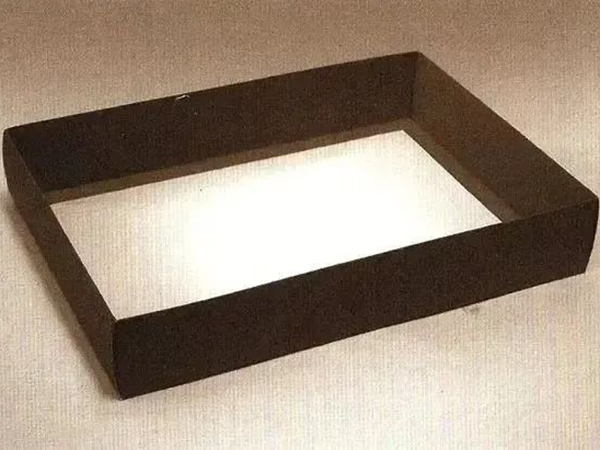

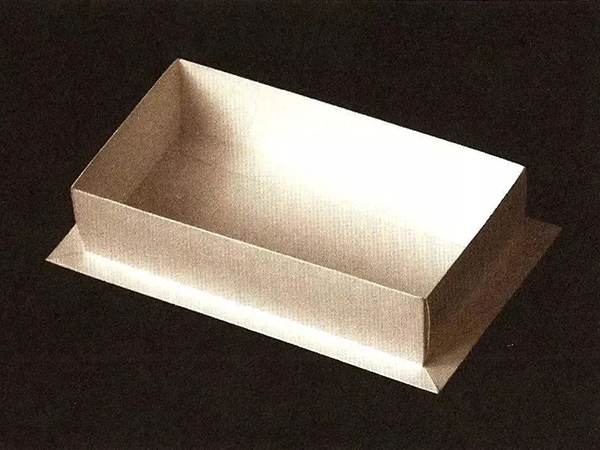

Disc packaging structure design

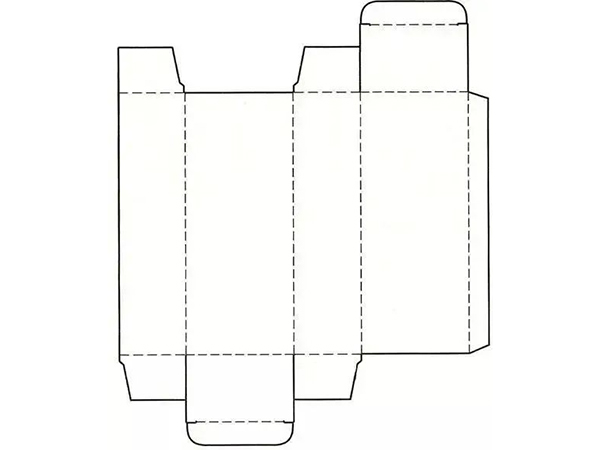

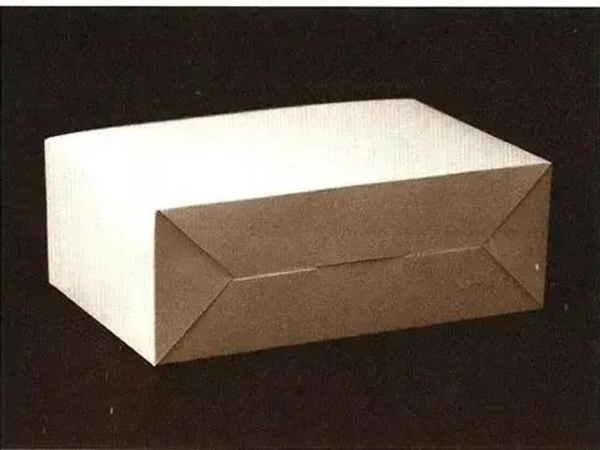

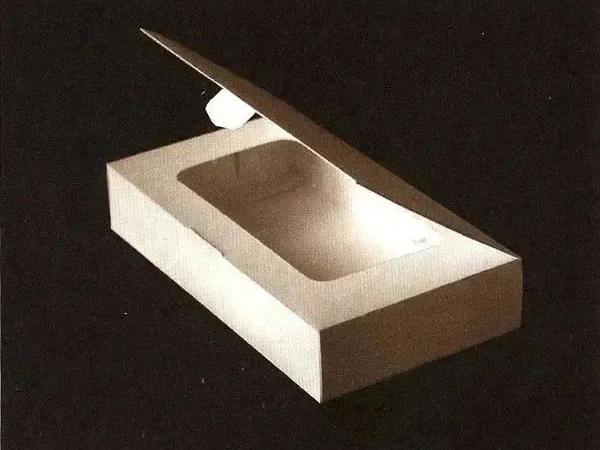

Disc type packaging box structure is formed by the cardboard around the folding, insertion or bonding of the box structure, this kind of packaging box at the bottom of the box is usually no change, the main structural changes reflected in the box body part. The tray type packing box is generally small in height, and the display surface of the commodity is larger after opening. This kind of carton packing structure is mostly used for packing textiles, clothing, shoes and hats, food, gifts, crafts and other commodities, among which the world cover and aircraft box structure is the most common form.

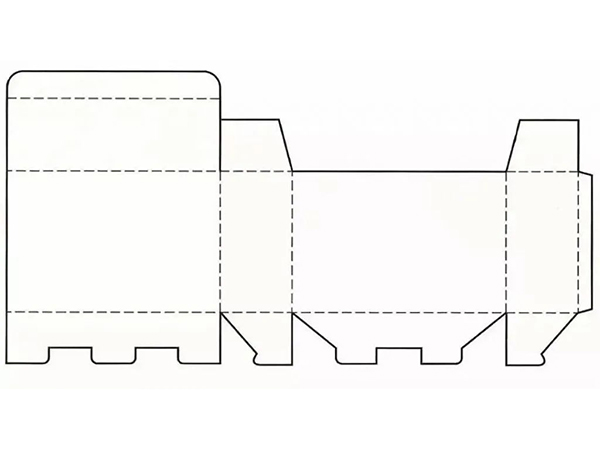

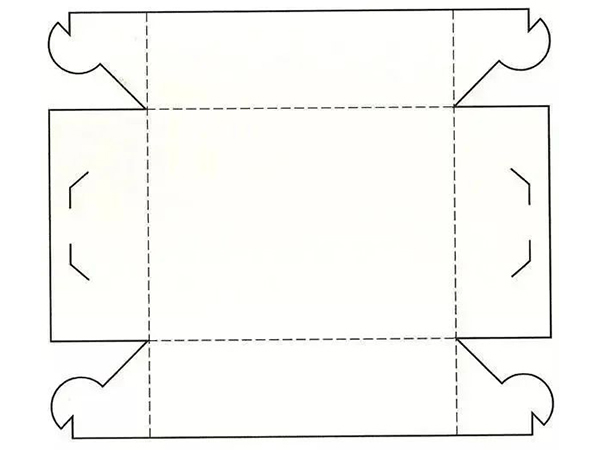

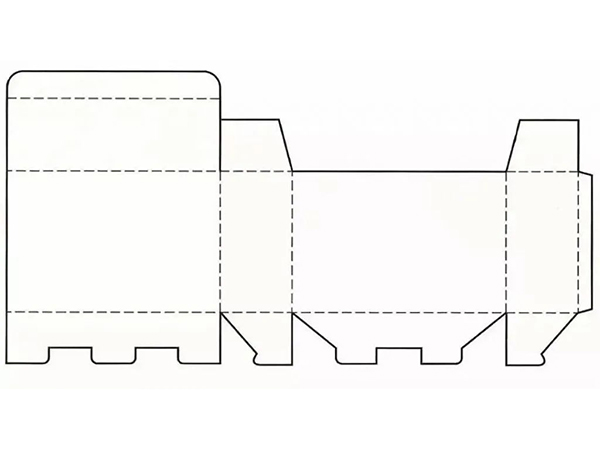

(1)The main molding method of the unfolding box

01

Forming and assembly No bonding and locking, easy to use.

The case cover has three parts of the shaking cover, the main cover has an extended tongue, in order to insert the case body to play a closed role. Attention should be paid to the occlusal relation of the rocking cover in the design. This cover is most widely used in tubular boxes.

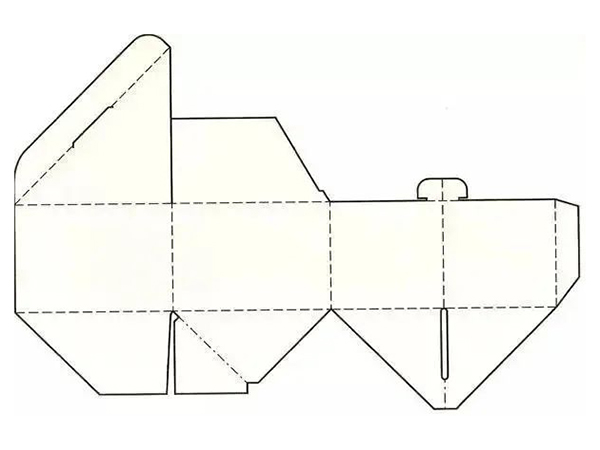

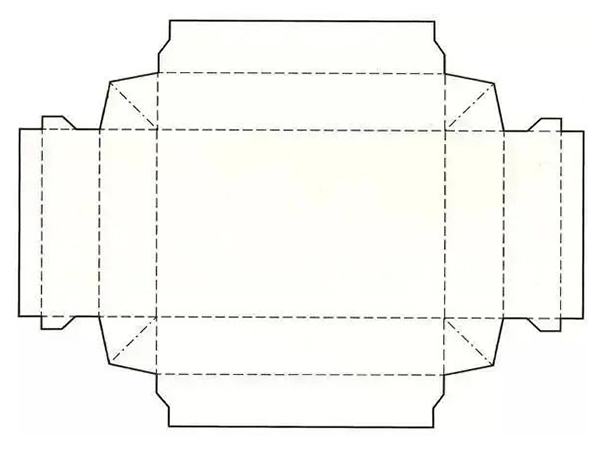

(Insert swinging cover structure expansion diagram)

(Structure expansion diagram of latch type box cover)

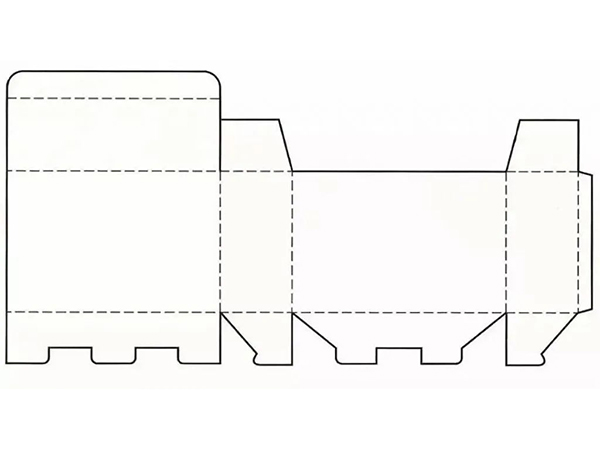

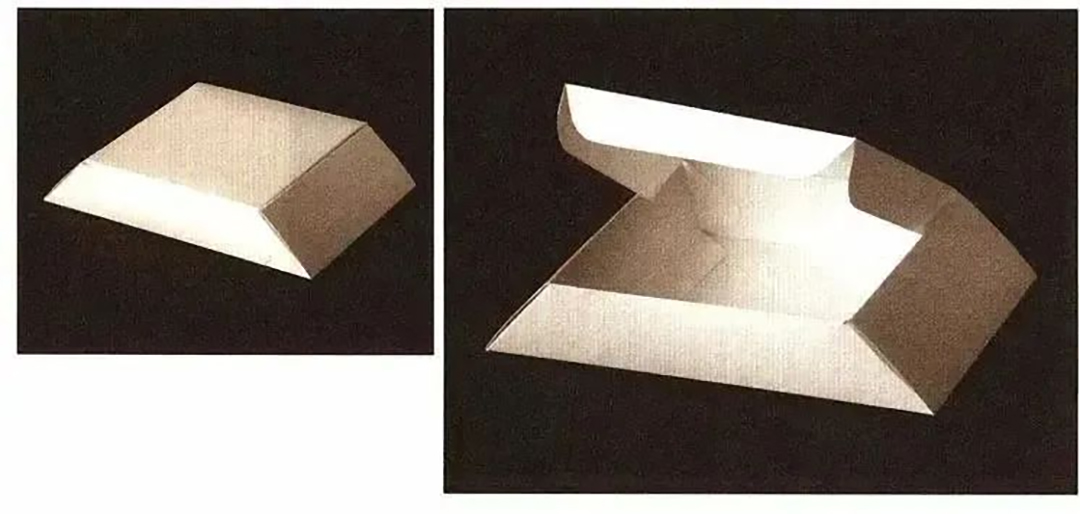

(Assembly structure expansion diagram)

(Assembly structure expansion diagram)

02

Lock or assembly

The structure is reinforced by locking.

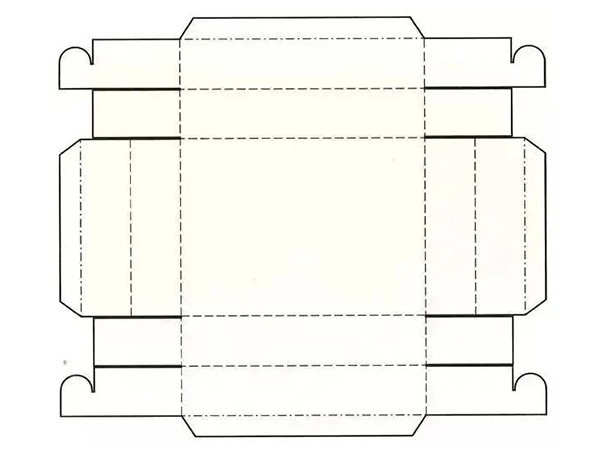

(Expanded view of locking assembly structure)

03

Pre glued assembly

The assembly is easier by local prebonding.

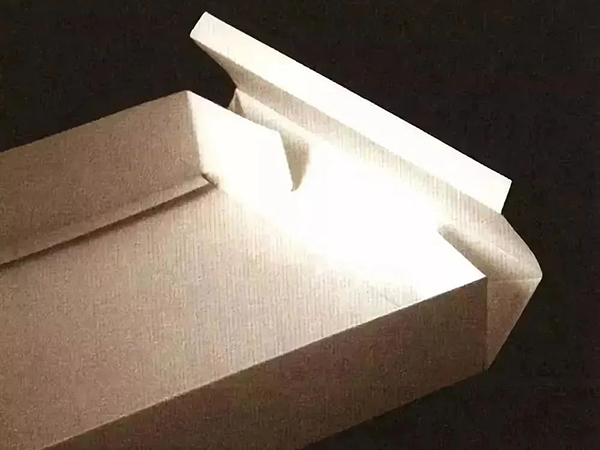

(2)The main structure of the unfolding box

1)Cover type: The box body is composed of two independent unfolding structures that cover each other, which is often used in the packaging of clothing, shoes and hats and other commodities.

2) Shake cover type: on the basis of the disc type packing box to extend one side of the design of shake cover, its structural characteristics are more similar to the shake cover of the tube type packing box.

(Double safety lock with cover type structure expansion diagram)

(Expansion diagram of trapezoidal structure with cover)

3) Continuous insertion type: the insertion mode is similar to the continuous wing flap type of tubular packaging box.

4) Drawer type: composed of two separate parts: tray box body and coat.

5) Book type: The opening mode is similar to that of hardcover books. The shake cover is usually not inserted and fastened, but fixed by attachments.

The structure design of single carton box is basically the above. Due to the development of packaging industry and the change of design, more packaging structure design can be evolved in the future.

Post time: Nov-16-2022