"Partition" or "Divider"? I believe many people, like me, haven't even realized there's a difference between the two, right? Here, let's firmly remember that it is "Divider" "Divider" "Divider". It also has common names such as "Knife Card" "Cross Card" "Cross Grid" "Insert Grid", and so on.

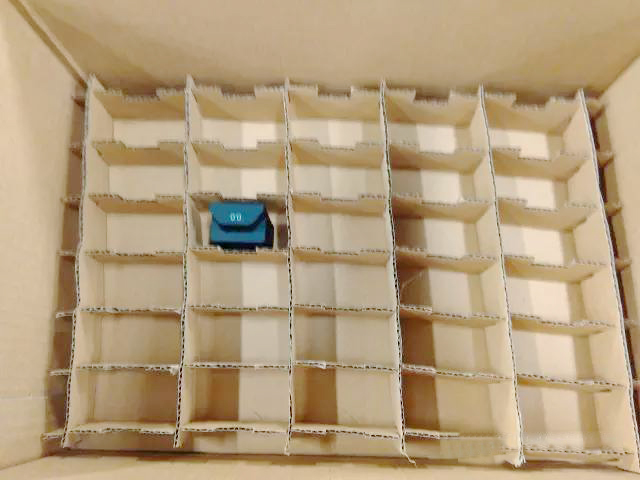

Definition of Divider A divider is a packaging component used to divide a large space into several smaller ones, to fix internal objects and relieve friction and collision damage between objects.

Common materials used in designing "Dividers" "Divider" is a very common type of "divider" in the packaging industry, commonly used in beverage, daily necessities, industrial products and other commodity packaging boxes. The materials used for paper dividers are: hollow board, corrugated paper, foamed PP board, white cardboard, and so on.

Styles of Dividers Dividers can generally be divided into two styles: open dividers and closed dividers. Among them, closed dividers can be designed into two styles: with bottom structure and without bottom structure.

Closed Divider:

Open Divider:

Comparison of the advantages and disadvantages of closed and open dividers

Closed Divider

|

Advantages: ·Better protection for the outermost products. ·Better buffering performance. ·Not easy to scatter, more convenient to take out. |

Disadvantages:·The material cost is relatively high compared to open dividers.

·For dividers of the same specification, the size of each individual grid is relatively smaller. ·Lower utilization of product space. |

Open Divider:

| Advantages:·More material-saving, lower cost.

·For dividers of the same specification, the size of each individual grid is relatively larger. ·Higher utilization of product space. |

Disadvantages:·Due to direct contact between the product and the container, a layer of protection is reduced.

·Poor buffering performance. ·The formed divider is prone to scatter. |

When designing packaging dividers, we need to consider the specific needs of the product, the cost, the utilization of space, and the protection of the product. Choosing the right type of divider can not only save materials and costs but also better protect the product during transportation and storage.

In addition to the commonly used materials for designing package dividers mentioned above, there are also other materials that can be used depending on the specific needs of the product. For example, if the product is fragile and needs extra protection, foam or bubble wrap can be used as a material for the dividers. On the other hand, if the product is heavy and requires a sturdy divider, plastic or metal can be used.

It is also worth noting that the design of the package divider can be customized based on the product being packaged. For example, a package divider for a set of glasses may have individual compartments for each glass, while a package divider for a set of utensils may have larger compartments to hold multiple utensils. The design can also take into account the shape and size of the product, as well as the desired packaging configuration.

In conclusion, package dividers are an essential component of product packaging, especially for products that are fragile or prone to damage during transportation. By using the right materials and design, package dividers can effectively protect products from damage, reduce the likelihood of returns and refunds, and enhance the overall customer experience.

Post time: Mar-30-2023